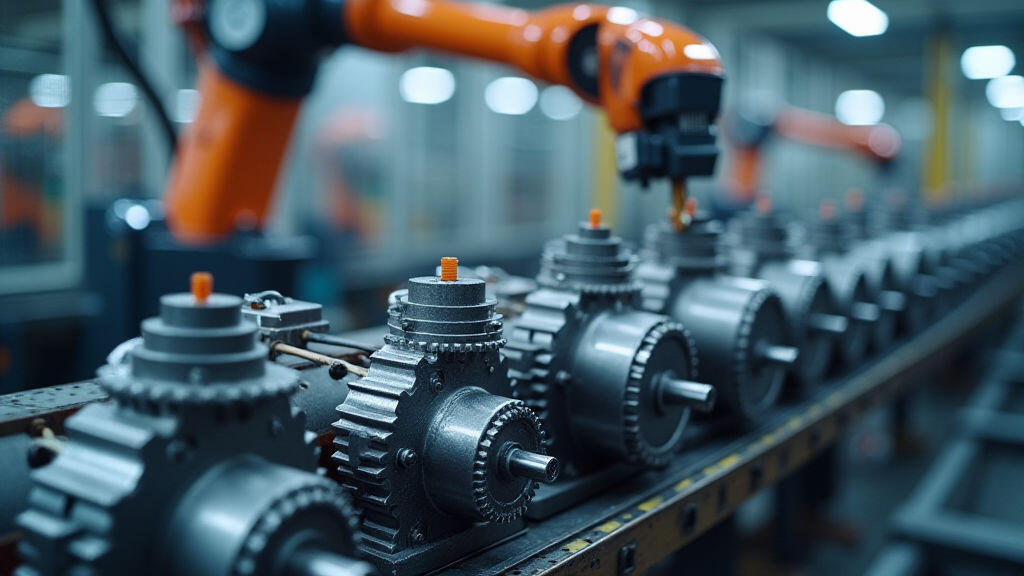

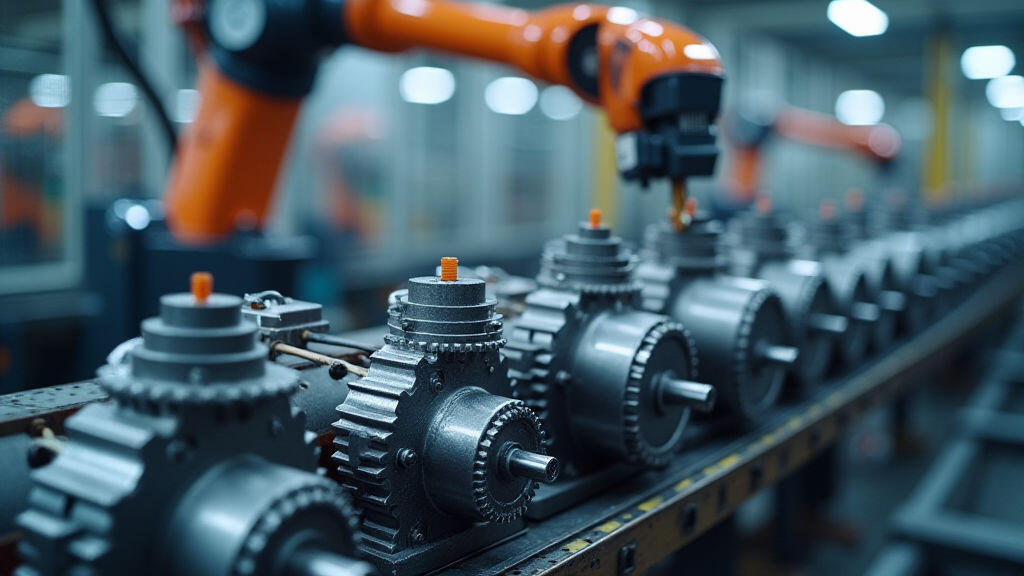

The modern manufacturing landscape is rapidly evolving. Driven by the need for increased efficiency, precision, and flexibility, automated production lines are becoming increasingly prevalent. This shift, coupled with the ongoing push for Industry 4.0 and smart factories, necessitates continuous upgrades to existing automation systems. A critical component in these upgrades is the gear motor – the workhorse that converts electrical power into mechanical motion, providing the force and speed needed for a vast range of applications. Choosing the right gear motor and ensuring its proper matching to the application isn't just important; it’s essential for maximizing the return on investment and ensuring the long-term reliability of your automated production line. This guide will walk you through the key considerations for gear motor selection and matching, equipping you with the knowledge to make informed decisions.

Gear motors are integral to almost every aspect of automated manufacturing. They power robotic arms, conveyor belts, pick-and-place systems, packaging machines, and countless other processes. They provide precise control over speed and torque, enabling delicate operations as well as heavy-duty tasks. The selection of an appropriate gear motor directly affects the performance, accuracy, and longevity of the entire automated system. Incorrect motor sizing or inappropriate gear ratios can lead to performance bottlenecks, premature equipment failure, and costly downtime – all factors that directly impact profitability.

Before diving into selection, it's crucial to understand the fundamental parameters that define a gear motor's performance:

Matching a gear motor to an application requires a systematic approach:

In many automated production lines, precision and accuracy are paramount. This is especially true in industries like electronics manufacturing, pharmaceuticals, and aerospace. Gear motors used in these applications must offer high resolution and minimal backlash (the amount of play in the gears). High-precision gear motors are typically used with closed-loop control systems to ensure accurate positioning and movement.

Navigating the complexities of gear motor selection can be challenging. MES-Drive offers a comprehensive range of high-quality gear motors and expert technical support to help you find the perfect solution for your automated production line. From standard industrial gear motors to custom-engineered solutions, MES-Drive is committed to delivering reliability, performance, and value. Our engineers work closely with customers to understand their specific requirements and provide tailored recommendations. We utilize advanced simulation tools to optimize gear train designs for maximum efficiency and minimal noise.

The future of gear motor technology is intertwined with the rise of Artificial Intelligence (AI) and the Internet of Things (IoT). AI-powered predictive maintenance systems can analyze gear motor performance data to identify potential failures before they occur, minimizing downtime and reducing maintenance costs. IoT connectivity enables remote monitoring and control of gear motors, allowing for real-time optimization of production processes. Furthermore, advancements in materials science are leading to the development of lighter, stronger, and more efficient gear motor designs.

The demand for automation is only going to increase. As companies embrace Industry 4.0 and smart factory initiatives, the role of reliable and efficient gear motors will become even more critical. Choosing the right gear motor, and ensuring its proper matching to the application, is no longer a secondary consideration – it's a strategic imperative for success. MES-Drive is poised to be your trusted partner in navigating this rapidly evolving landscape.

Selecting and matching gear motors for automated production line upgrades requires a thorough understanding of application requirements, motor parameters, and technological advancements. By following a systematic approach and considering factors like torque, speed, gear ratio, efficiency, and environmental conditions, you can ensure optimal performance, reliability, and longevity. With the convergence of AI and IoT, the future of gear motor technology promises even greater efficiency, precision, and predictive capabilities. As manufacturers seek to optimize their operations and embrace Industry 4.0, intelligent gear motor solutions are set to play a pivotal role in achieving their goals. MES-Drive is dedicated to providing the innovative gear motor solutions and support you need to thrive in the era of smart manufacturing.

Leave A Reply

Your email address will not be published. Required fiels are marked